Save Up to 15,000 Euros!

As previously announced, our support for the GSM 3000 series is ending. Effective January 1, 2025, we will no longer offer maintenance and repair services for the GSM 3000. If you still own a GSM 3000 device, we have an exciting offer for you.

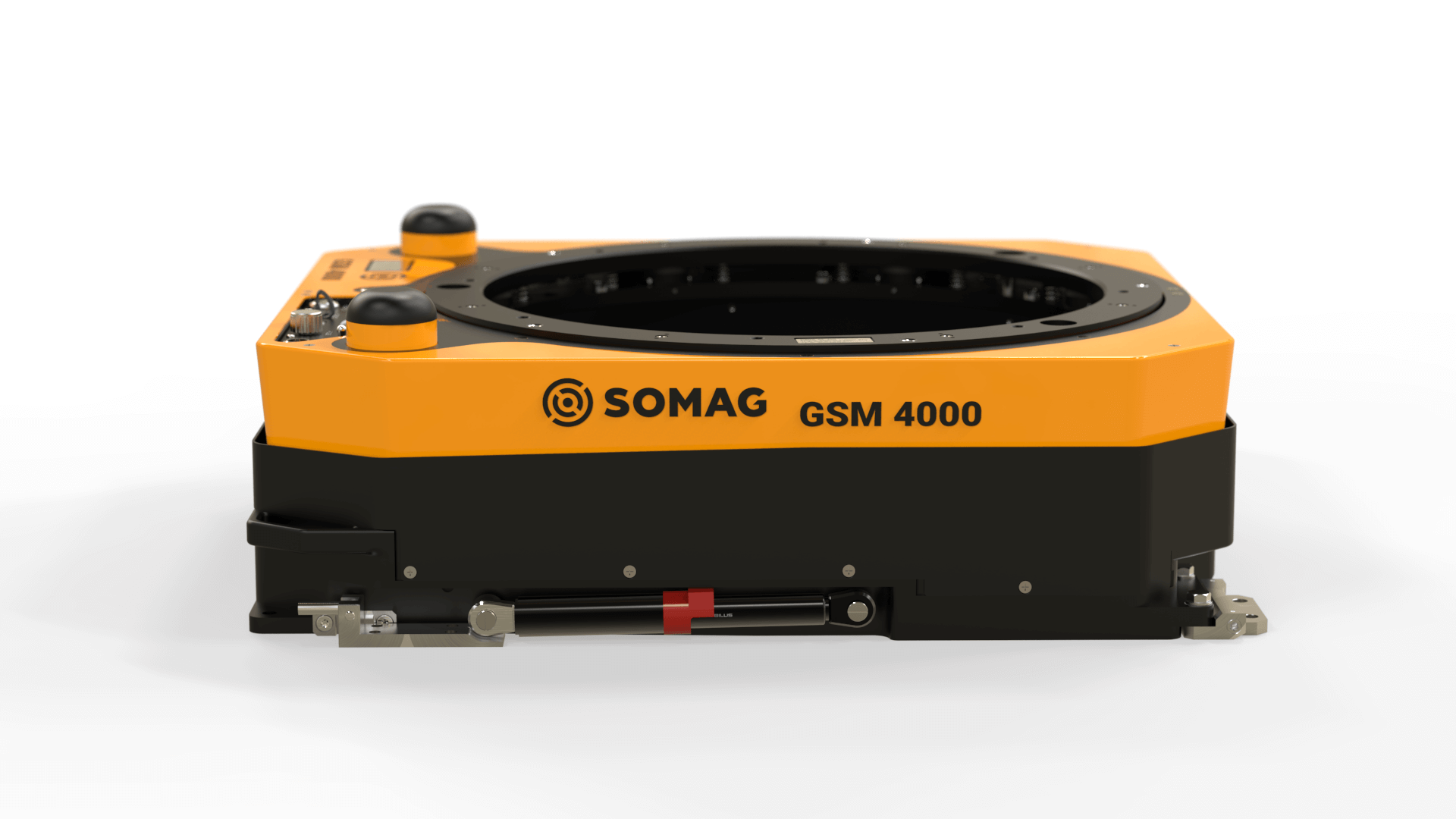

To make this transition easier, we have prepared an unbeatable offer for our customers: trade in your current GSM 3000 for its successor, the GSM 4000, and and save up to 15,000 euros! This limited-time offer is available to our valued customers who want to stay ahead with the latest technology.

Why upgrade to the GSM 4000?

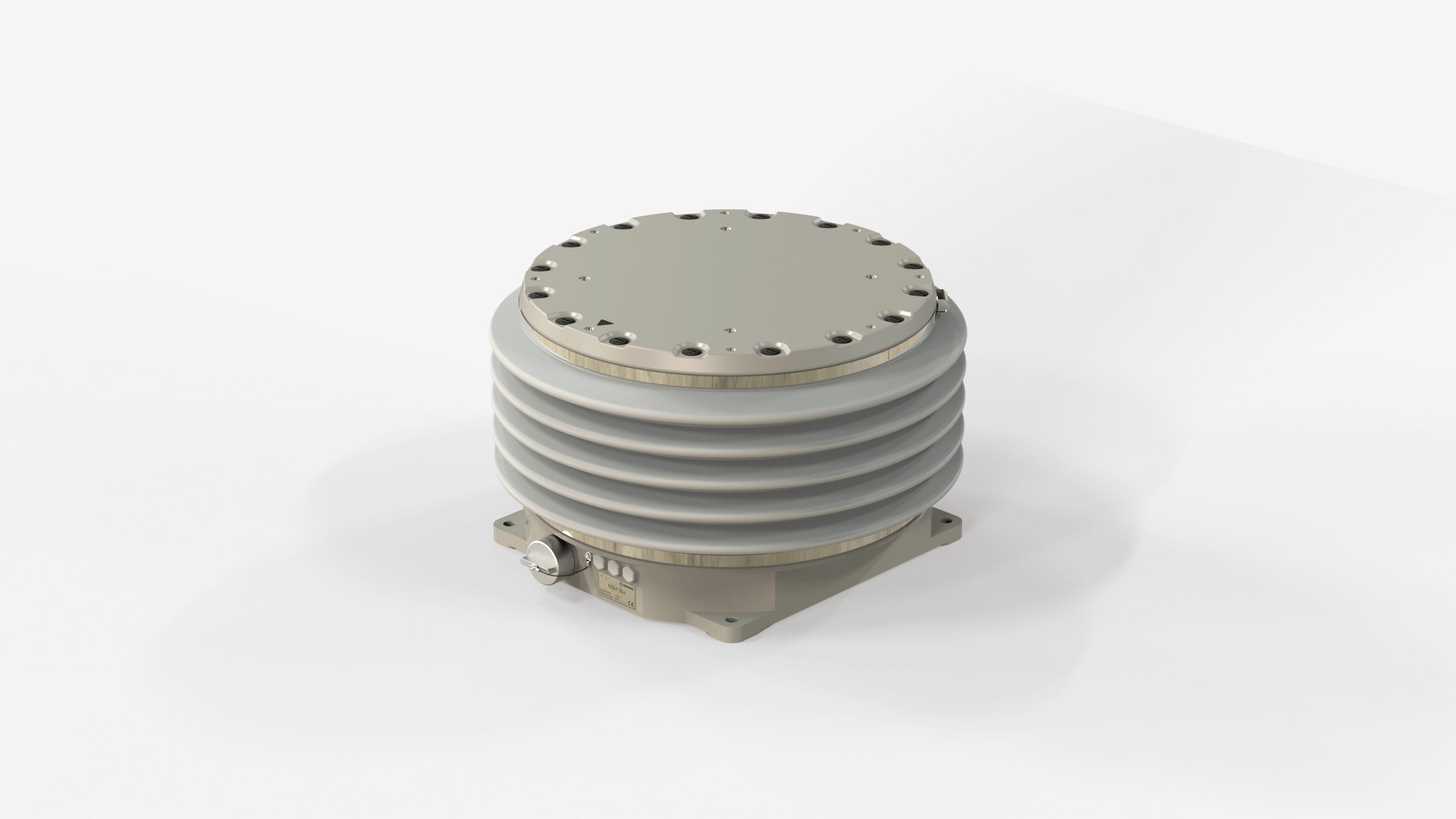

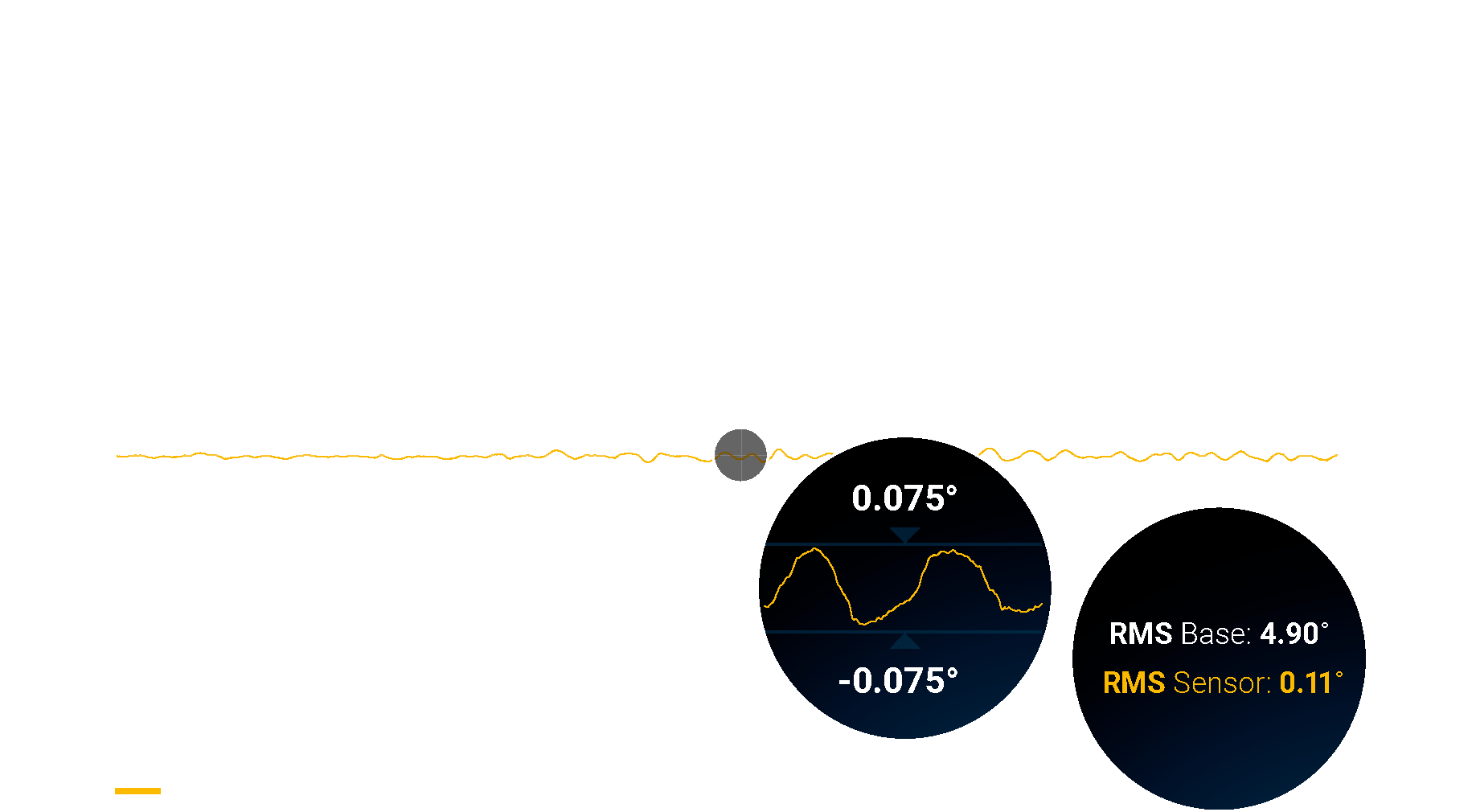

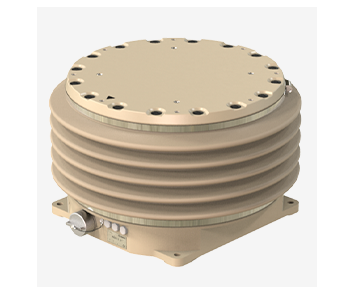

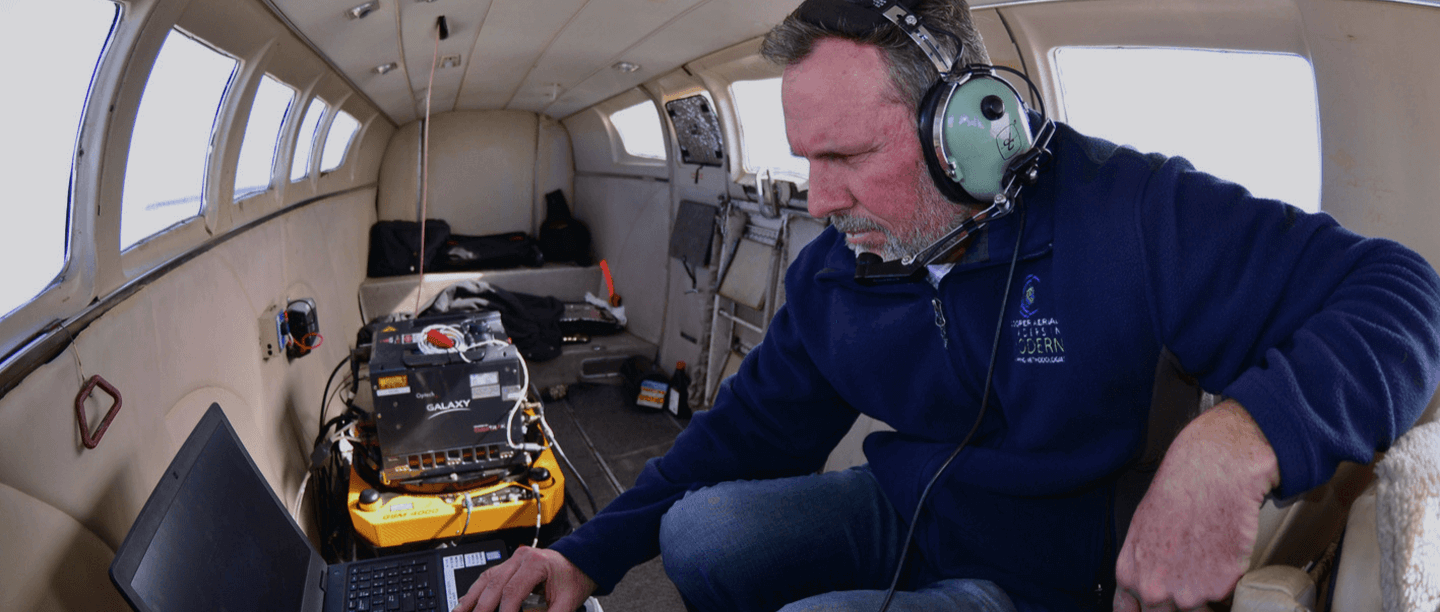

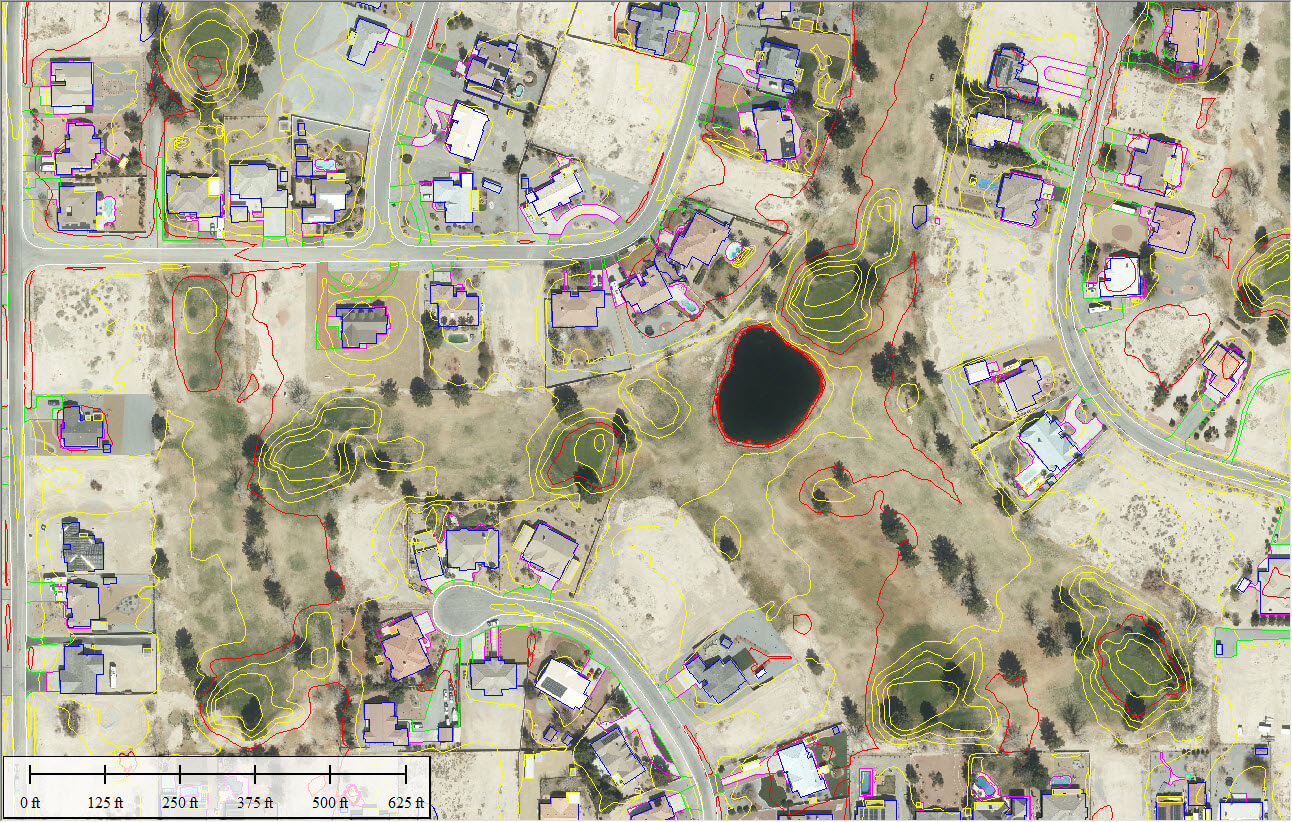

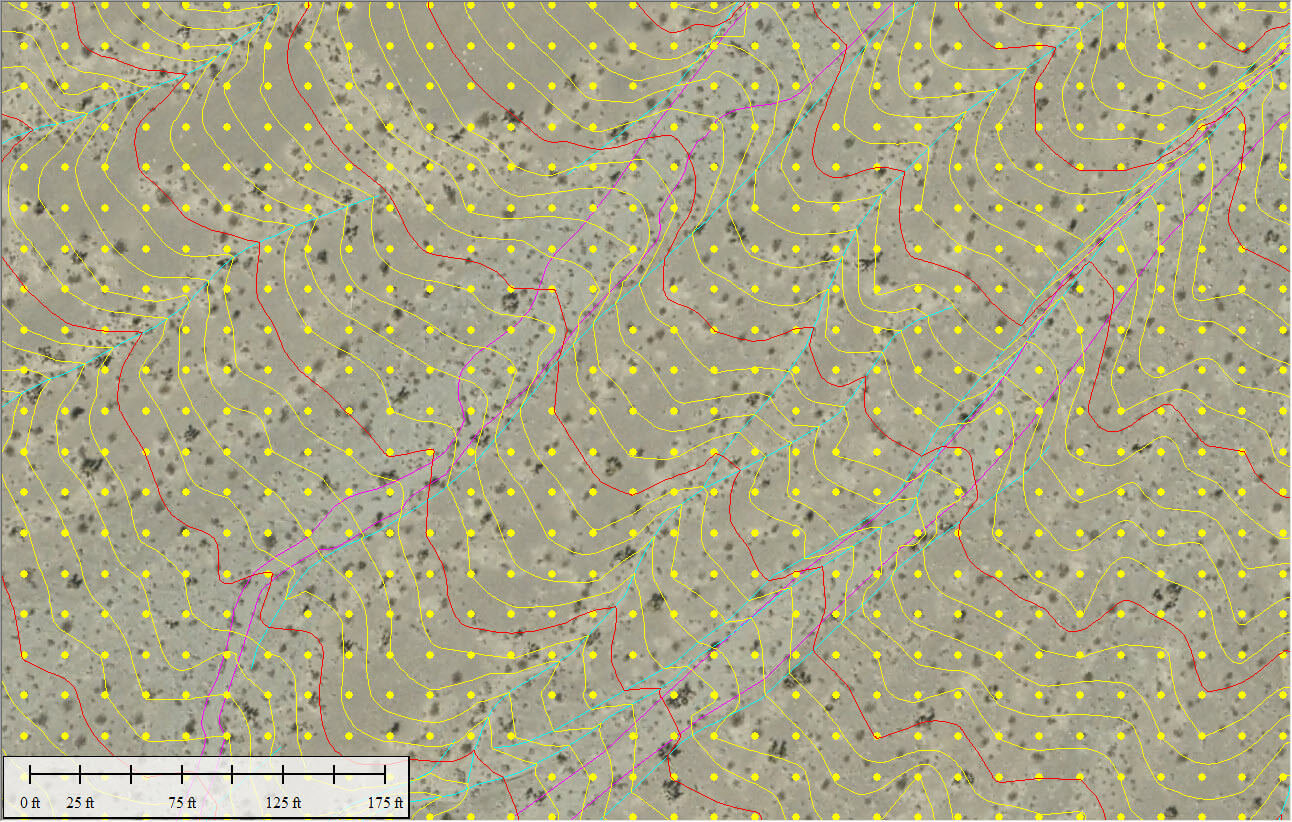

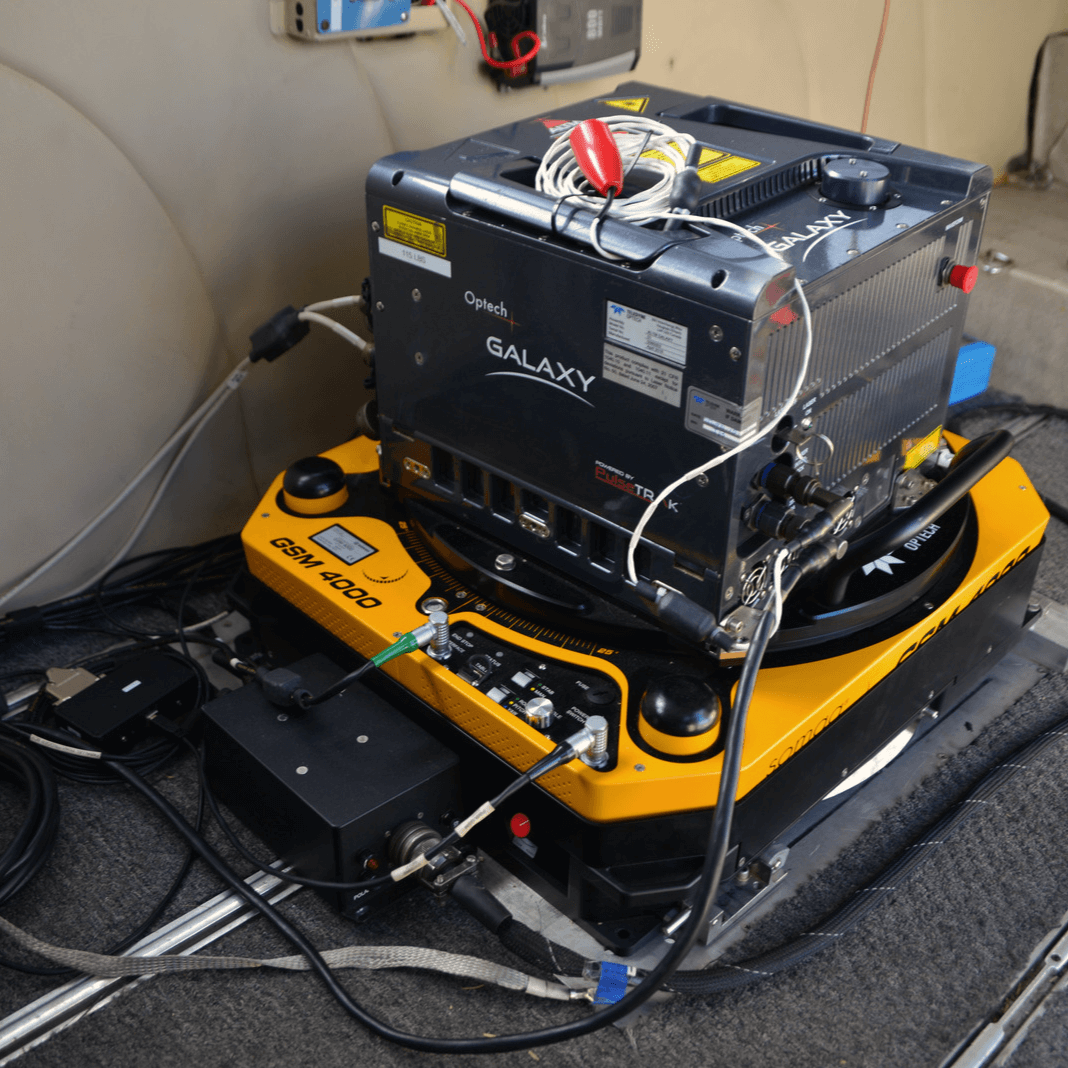

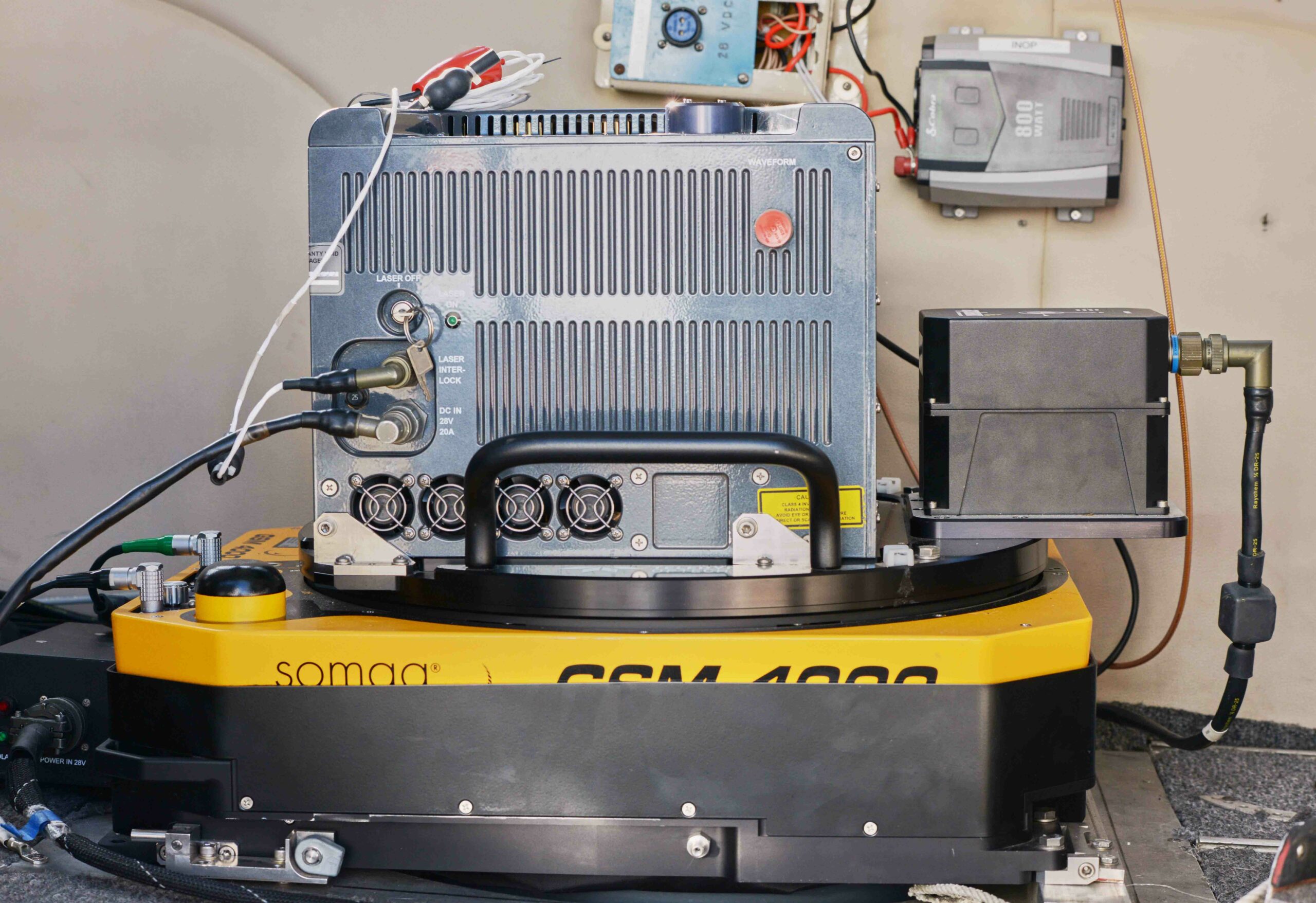

The GSM 4000 sets the benchmark for large format cameras and scanners, offering unparalleled stability and performance for airborne surveying. The Gyro Mount adapts to any sensor and camera on the market, providing maximum flexibility in equipping your aircraft. Its high level of stabilization is critical for achieving the best results in mapping, surveying, and remote sensing projects. By significantly enhancing the efficiency and precision of both airborne imagery and LiDAR data collection, the GSM 4000 ensures that your projects meet the highest quality standards.

How to take advantage

Ready to elevate your surveying technology? Contact our sales or support team directly to learn more about this offer and begin your trade-in process. Our experts are here to answer your questions and assist you every step of the way.

Don’t miss out on this unique opportunity to be at the forefront of surveying technology. The GSM 4000 is waiting for you!

Sales and Support

Sören Lieske

Sales Manager

Phone: +49 3641 633 68 18

E-Mail: s.lieske@somag-ag.de

Let’s connect on LinkedIn

Johannes Dreyer

Support Manager

Phone: +49 3641 633 68 17

E-Mail: j.dreyer@somag-ag.de

Let’s connect on LinkedIn

Subsrcibe today!

Keep yourself informed about SOMAG and the latest Gyro Mount technology.

We will send you regular information about:

- exhibitions and event invitations

- new products, services and videos

- latest application examples, projects and partnerships