Meet SOMAG at Apex 2025 | Gyro Stabilization for Defense & Surveillance

We are thrilled to announce that we will be attending Apex 2025, a premier defense innovation event taking place on April 23-24, 2025, at the Gaylord National Resort & Convention Center in National Harbor, Maryland.

Apex 2025 is designed to redefine collaboration among the U.S. military, allied forces, defense contractors, and cutting-edge technology companies. Its mission is to “deliver adaptable capability at speed and scale to the warfighter”. The event focuses on accelerating the delivery of high-impact, mission-critical solutions to address urgent operational challenges.

Our Sales Manager Sören Lieske will be available throughout the event to:

- Discuss your specific operational needs,

- Share insights into SOMAG’s innovative stabilization solutions, and

- Explore potential collaborations to enhance your defense and maritime operations.

Let’s Connect at APEX 2025!

If you’re attending the event and would like to arrange a meeting with our representative, please don’t hesitate to contact us. We look forward to insightful discussions and discovering how we can support your mission-critical operations.

Secure Your Spot – Let’s Discuss Your Stabilization Needs!

We are excited to see you in National Harbor, Maryland!

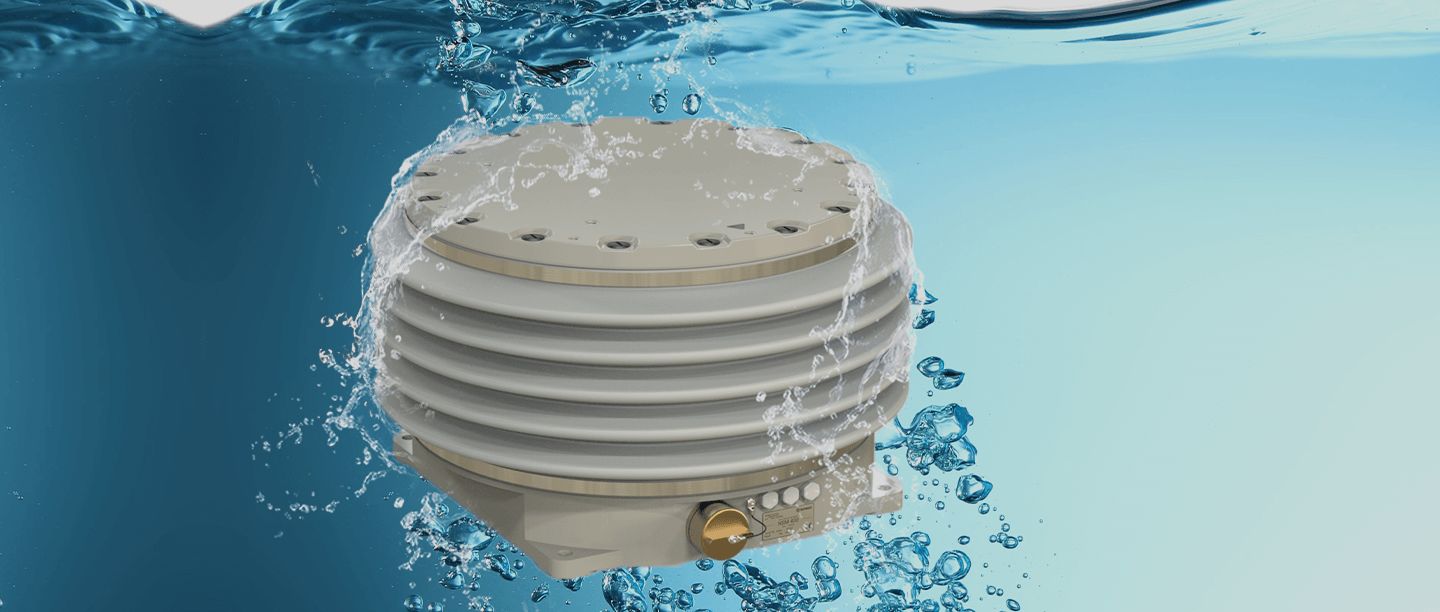

SOMAG Stabilization Solutions for Military Applications

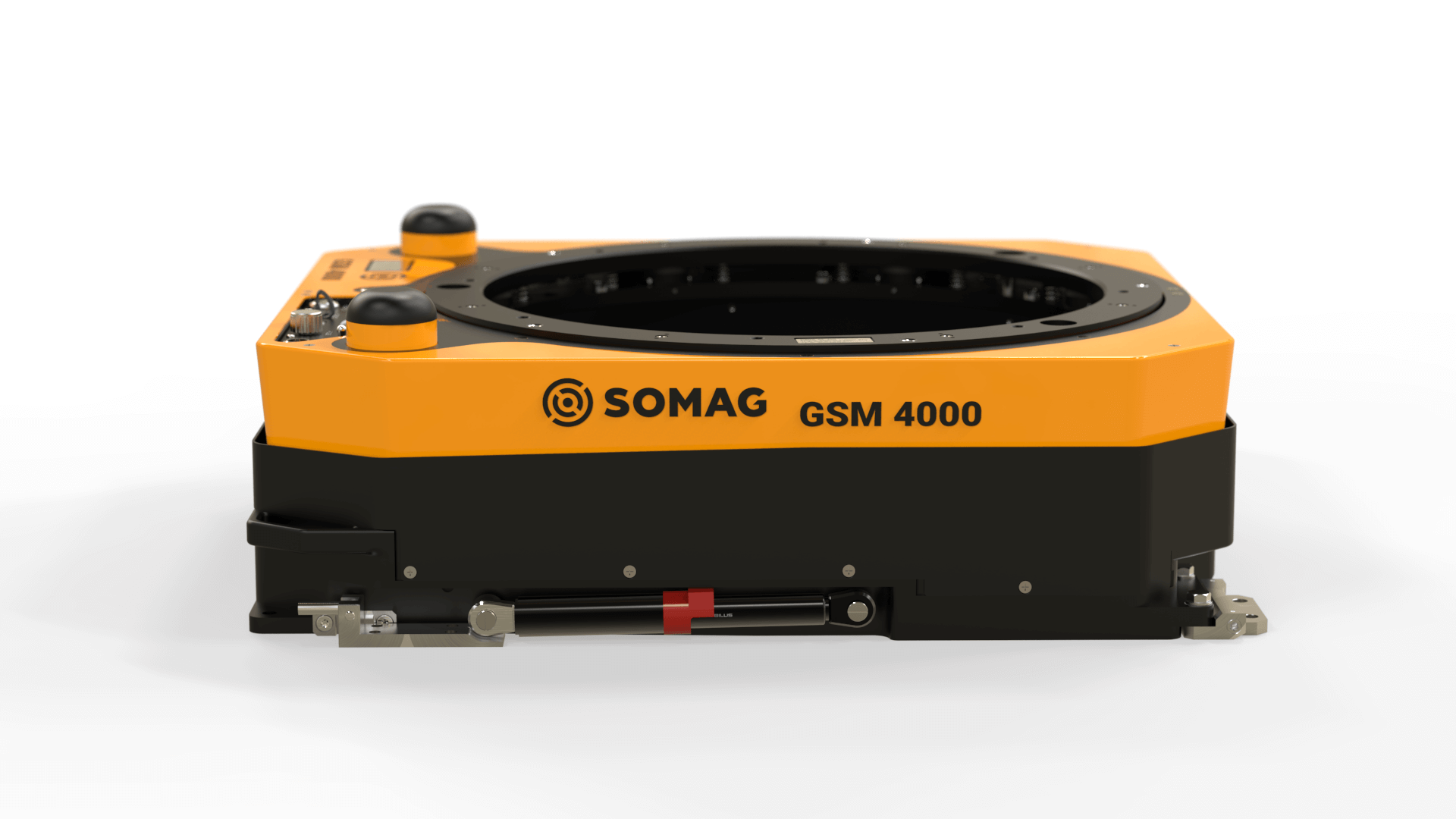

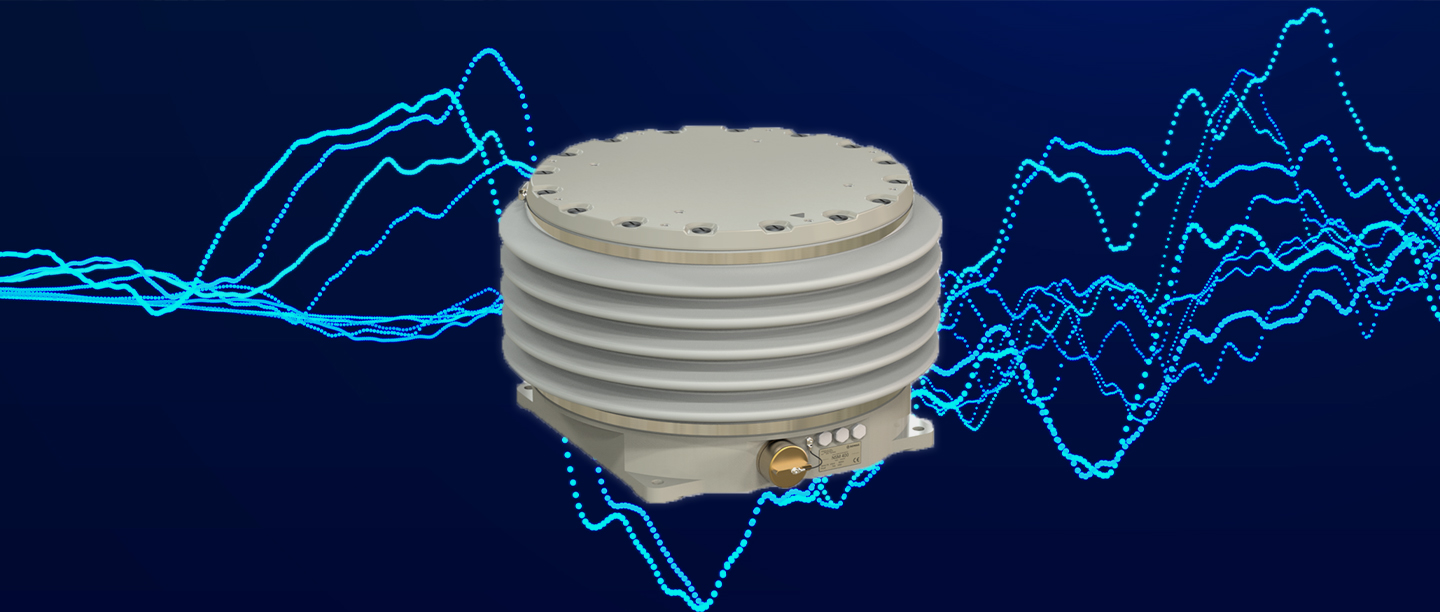

SOMAG AG Jena is a global leader in Gyro Stabilization Mounts, delivering cutting-edge stabilization technology for applications in air, land, and sea domains. Our solutions are mission-critical for military operations, where success often hinges on the precision and reliability of the information collected in dynamic and challenging environments.

Our Gyro Stabilization Mounts are specifically engineered to:

- Enhance imaging system performance: Compensate for vehicle motion to significantly improve the quality of data collected with EO/IR and other imaging systems.

- Support comprehensive situational awareness: Deliver stabilized and clear visuals, even under the most demanding conditions.

- Boost operational effectiveness: Provide unparalleled precision and stability in mobile environments across air, land, and sea.

Tailored for the unique demands of military missions, SOMAG mounts empower defense forces with high-quality surveillance, reconnaissance, and real-time target acquisition capabilities.