Gyro Mounts to successfully pass temperature tests

SOMAG AG Jena has successfully completed temperature tests on its airborne, marine and land Gyro Stabilization Mounts at the independent and accredited test laboratory MeßTechnikNord GmbH in Jena, Germany, which specializes in conducting climatic product tests, such as cold, heat, thermal shock, and humidity tests. The temperature tests are part of a series of comprehensive environmental tests that the company performs at regular intervals, in addition to EMC and performance tests to ensure consistently high-quality standards for its devices.

Sebastian Schreiber, Chief Technology Officer at SOMAG, comments: “By means of environmental simulations, we can replicate environmental influences that occur in the course of a product life cycle to prove that our Gyro Mounts are able to face them. The analyses also help us to understand the different effects of extreme temperatures on the Mounts in operation, such as achieving the specified angles and angular velocities, as well as stabilization performance. In addition, it is important that we explore the limits of our devices.”

Temperature Tests Airborne Gyro Mounts

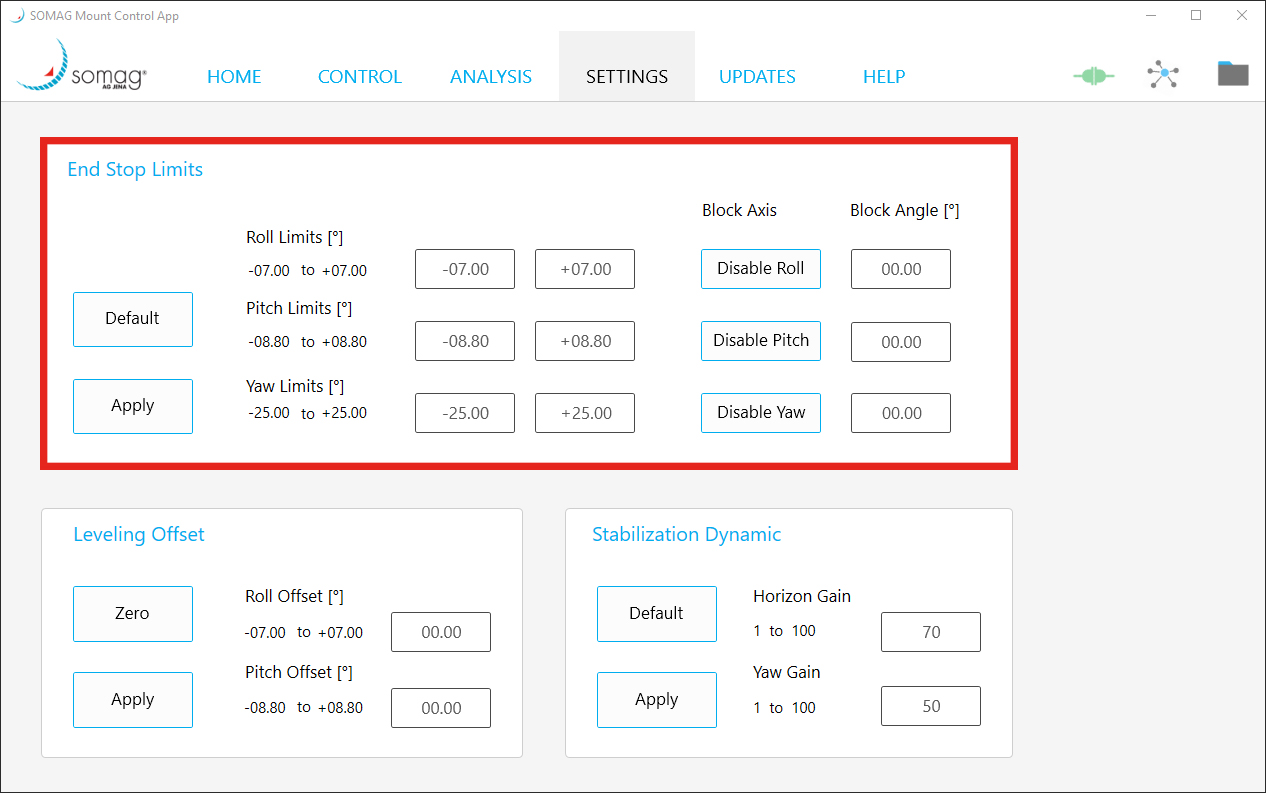

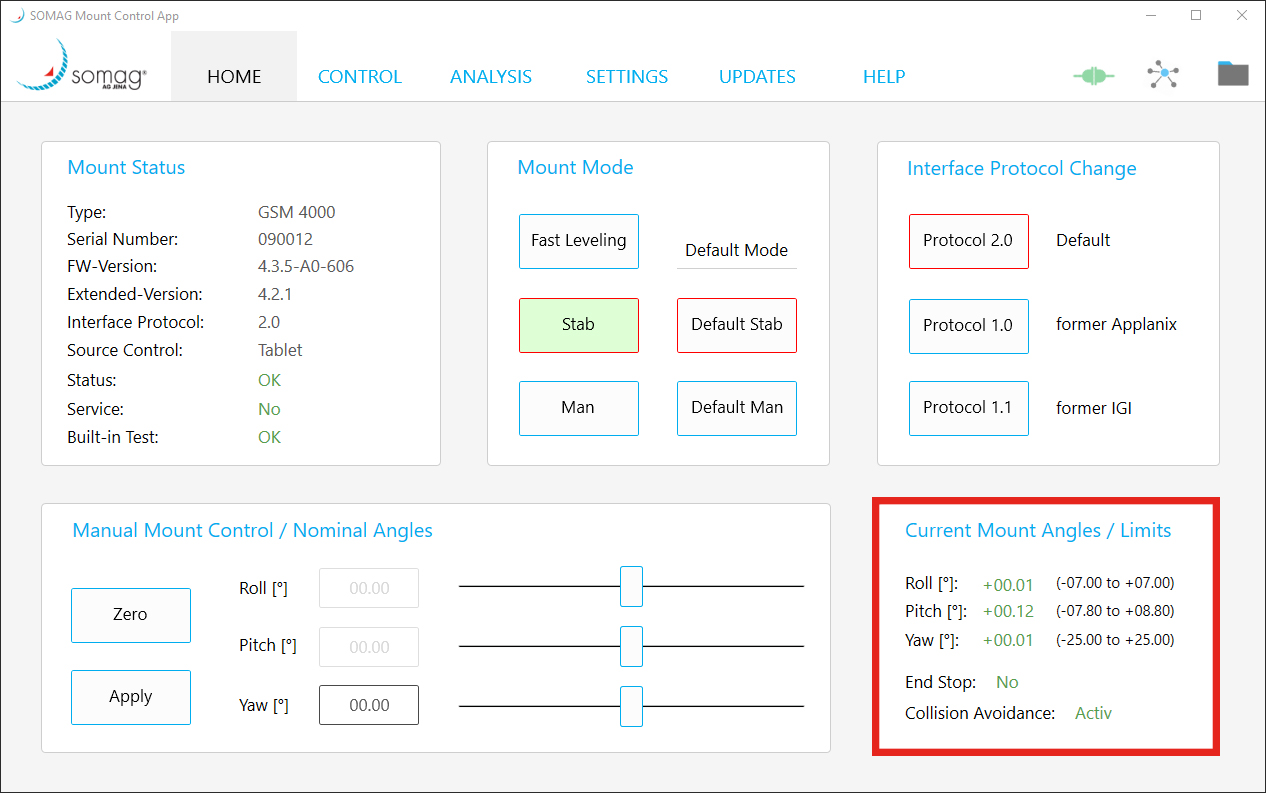

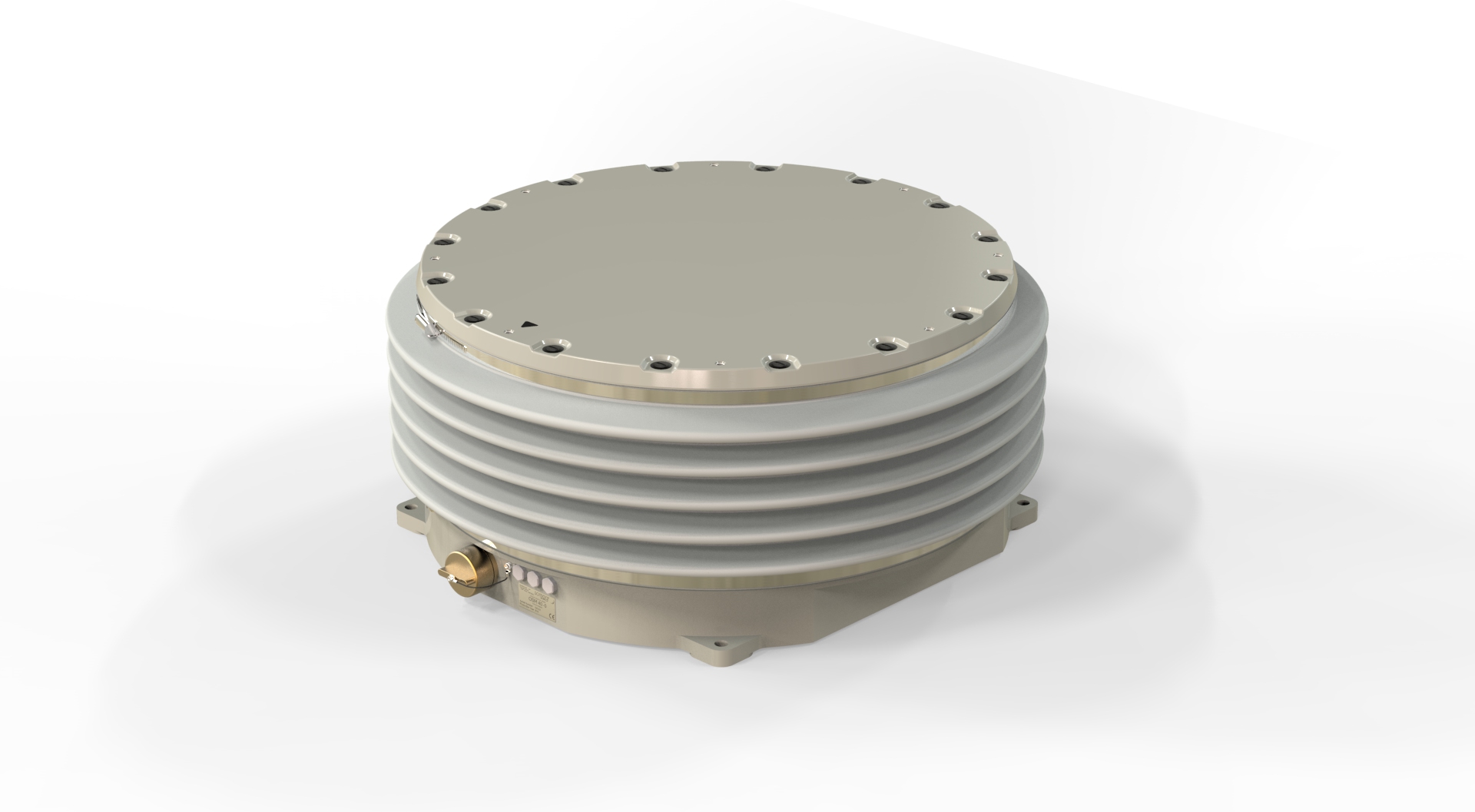

Tests were carried out on the GSM 4000 and DSM 400 Aerial Camera Stabilizers with their respective maximum payloads. The tests verified the acceptable temperature ranges for operation and storage given in the Gyro Mount specifications overview, which conforms to the RTCA DO-160 Equipment Section 4 / Temperature and Altitude / Category A1 standard:

| Category A1 | |

| Operating Low Temp. [°C] | -15 |

| Operating High Temp. [°C] | +55 |

| Ground Survival Low Temperature (Storage) [°C] | -55 |

| Ground Survival High Temperature (Storage) [°C] | +85 |

Both airborne gyro gimbals successfully passed the tests in the high and low temperature ranges. Beyond the limits of SOMAG specifications, the GSM 4000 kept performing well even at a minimum operating temperature of -32 °C.

Temperature Tests Marine/Land Gyro Mounts

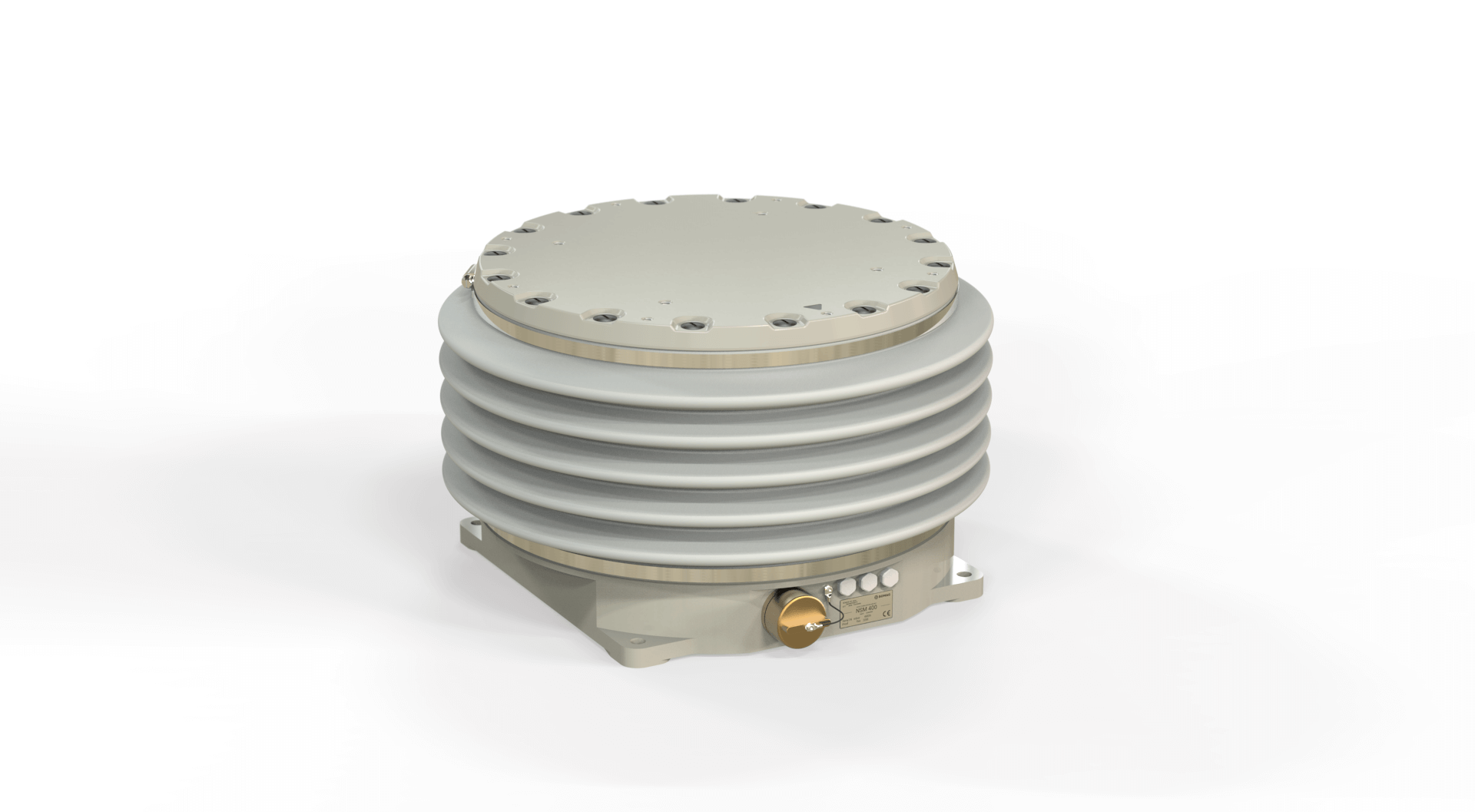

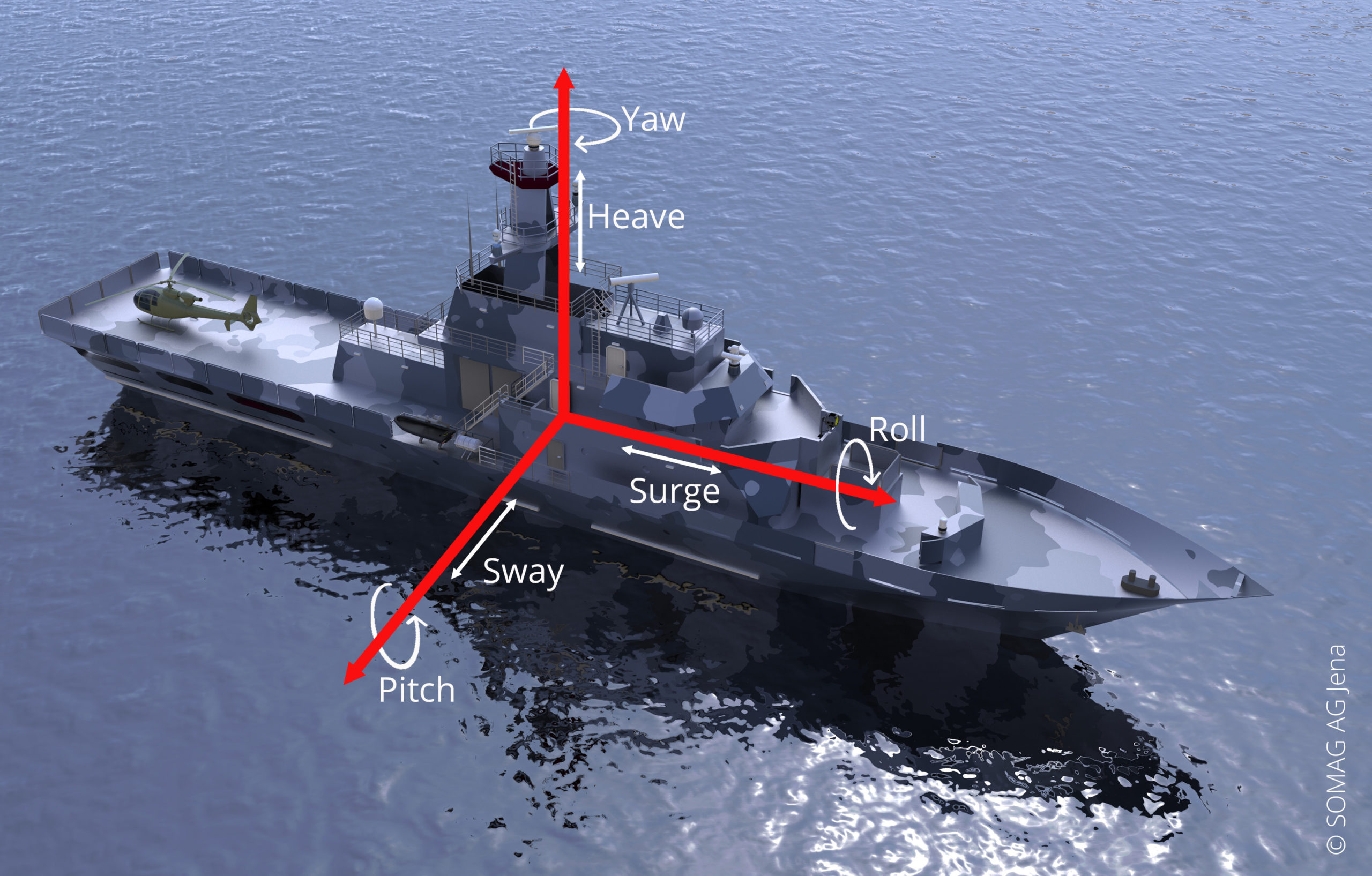

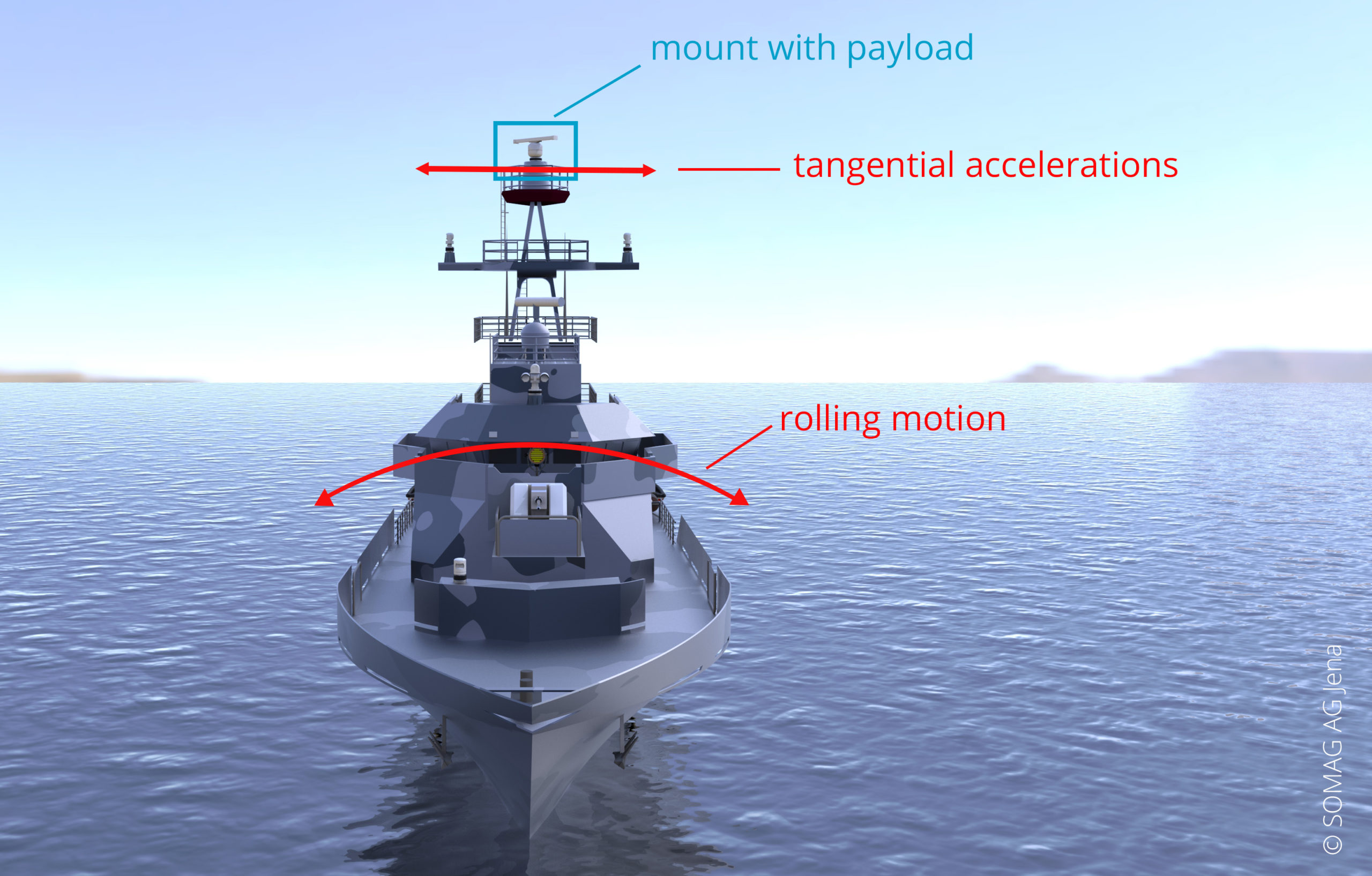

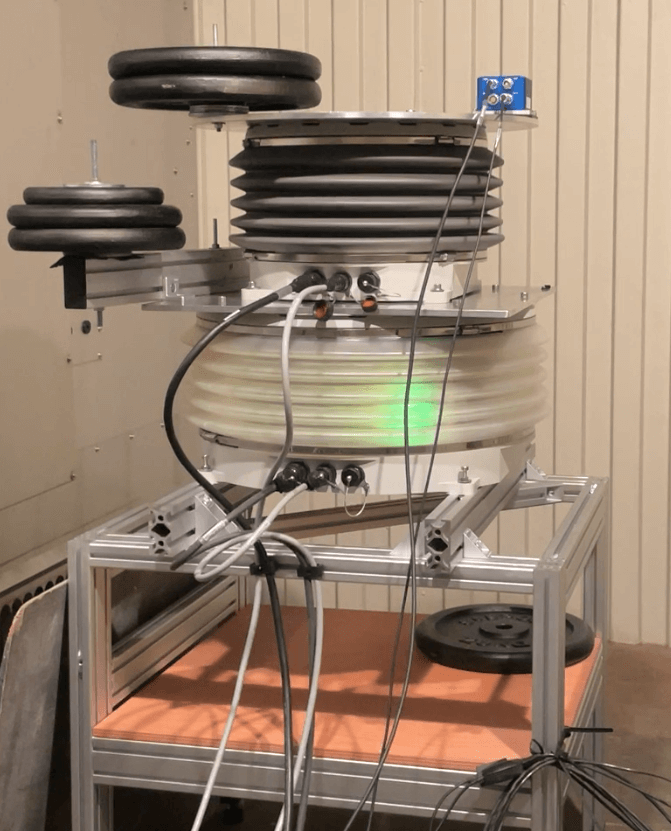

While airborne Gyro Stabilization Mounts are installed inside airplanes, the gimbals of the marine and land sector have to meet higher requirements. Installed up high on a mast of a frigate or on the back of an unmanned ground vehicle maneuvering through rough and dusty terrain, the Mounts in these application scenarios are directly exposed to harsh environmental influences such as blazing hot sun or freezing rain, which increases the stress on the material. However, even in these climatic conditions the Mount must prove that it can deliver its full power and achieve its specified performance and continuous torque. In the case of the NSM 400, this is 125 Nm and in the case of the OSM 4000, 225 Nm. This was tested by placing the payload off-center on the Mounts to setup a specific lever arm length to generate the continuous torque.

In the first phase, tests were carried out in accordance with the marine standards IACS E10 Rev. 7 and DNV-CG-0339. Both marine gyro platforms stabilized properly in the specified high temperature range up to 55 °C and in the low temperature range down to -25 °C with residual angles of 0.07° and less.

| SOMAG Marine Mount Specifications | |

| Operating Low Temp. [°C] | -30 |

| Operating High Temp. [°C] | +55 |

| Ground Survival Low Temperature (Storage) [°C] | -55 |

| Ground Survival High Temperature (Storage) [°C] | +85 |

“However, the requirements of our military customers go beyond this, just like our own specifications,” explains Arne Wollboldt, Application Engineer at SOMAG and responsible for environmental testing. NSM 400 and OSM 4000 demonstrated in the second stage that they performed perfectly even at -32°.

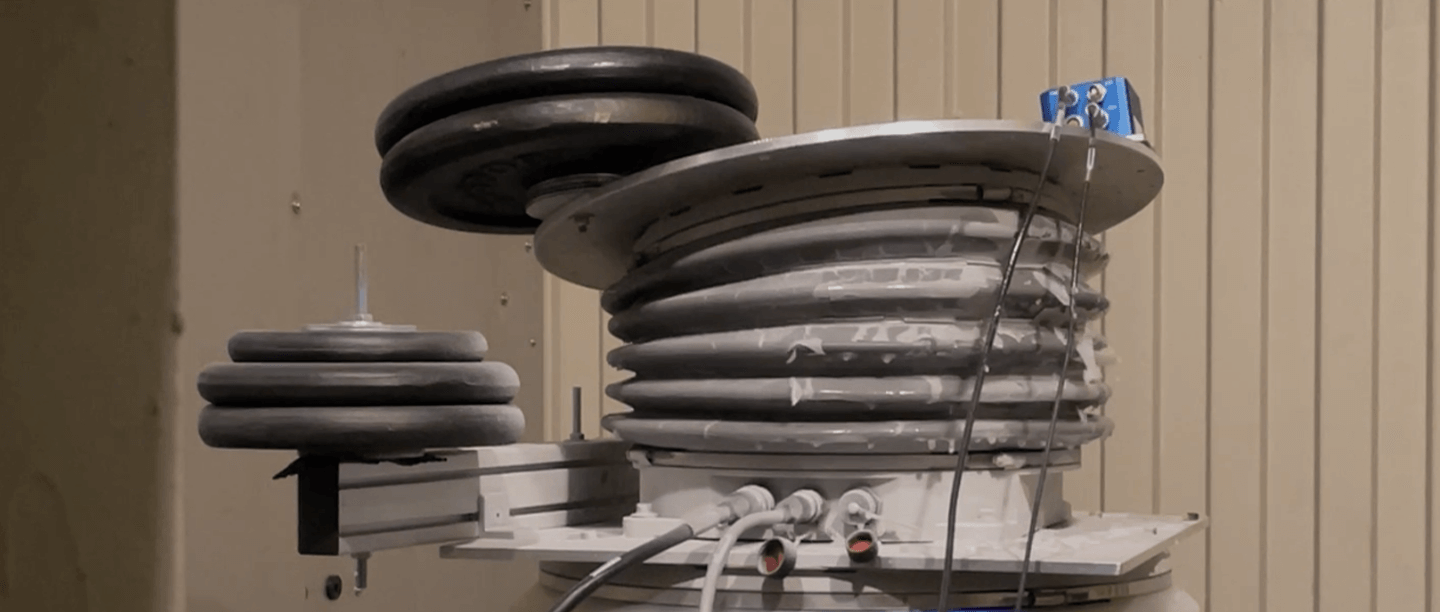

Wollboldt: “Up to this point, we had expected these results. But we wanted to see what would happen if we increase the difficulty and push the Mounts further, so we also tested an operating temperature down to -40 °C. An extraordinary cold, as it occurs for example in tundra regions and the arctic ocean. To create more natural conditions, we sprayed the NSM 400 with water and covered it with a layer of ice.”

A challenge that the surveillance sensor gimbal masters with flying colors. Thanks to its unique material, the protective bellow remains flexible and breaks the ice with the first movement, proving that the gimbal is capable of delivering best-in-class gyro stabilization for EO/IR systems even in extreme weather conditions.

Video Marine Gyro Stabilizer Temperature Test

Subscribe today!

Keep yourself informed about SOMAG and the latest Gyro Mount technology.

We will send you regular information about:

- exhibitions and event invitations

- new products, services and videos

- latest application examples, projects and partnerships